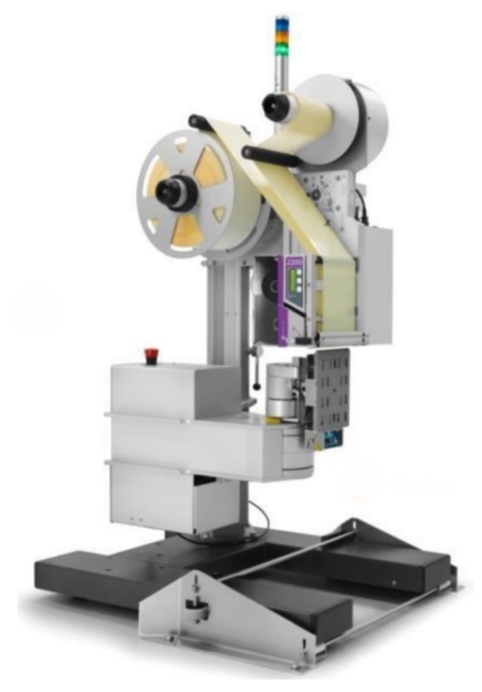

Markem-Imaje 2200

-

2200 Series: Enhancing Operational Efficiency

Safety and Ease of Use

Operators can achieve proficiency with less than 5 minutes of training.

Optimized Human-Machine Interaction

Standard three-button graphical operation panel, with an optional color touchscreen production interface, ensuring only core operational parameters are displayed.

Efficient Media Management

Supports extended media capacity for prolonged continuous operation. Synchronized media reloading technology allows for label and ribbon replenishment in less than 40 seconds.

Unmatched Reliability

High-Standard Barcode Quality

Complies with ANSI A/B grade barcode standards even at maximum operating speeds. Integrated barcode scanners ensure of shipped cartons have readable barcodes.

Convenient Maintenance Design

Enables quick replacement of wear parts. Daily maintenance requires no complex calibration or specialized tools.

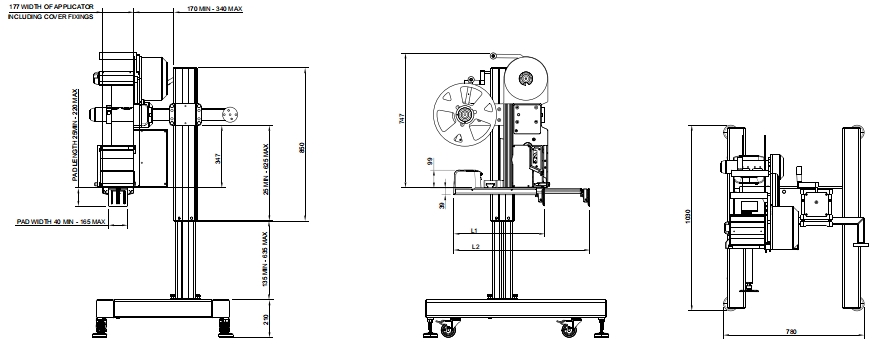

Diverse Adapter Configurations

Offers a wide range of adapter options to precisely match various application scenarios, minimizing production line adjustments and costly modifications.

High-Performance Printing System

Speed, Reliability, and Intelligent Error Prevention

Equipped with the AI-powered "Touch-S" system to prevent labeling errors in real-time, ensuring product integrity and improving Overall Equipment Effectiveness (OEE).

Seamless Redundancy Switching Mechanism

Built-in automatic switching/dual-machine tandem function. When a 2200 series device goes offline, the backup labeler immediately takes over, achieving zero downtime production.

Fully Automated Label Control

Integrated stable label management module with automatic tension adjustment and unified label control system, eliminating the need for manual adjustments and calibration.

Award-Winning Technology: Empowering Production Line Efficiency

The 2200 series is built on a proven architecture, with thousands of units deployed in demanding 24/7 operating environments. It excels in reliability, efficiency, and ease of use, significantly reducing coding error rates. Designed with over 95% recyclable materials, it elevates printing and labeling technology to new heights, featuring the following breakthrough characteristics:

Modular and Interchangeable Applicator System

Supports rapid switching for multi-scenario applications, adapting to diverse production line needs.

ü Intelligent Operational Intervention

Minimizes manual intervention through predictive maintenance algorithms.

Industry-Leading Application Speed

Breaks traditional equipment throughput limits.

Summary

The 2200 series combines cutting-edge technology with user-friendly design to deliver unmatched reliability, efficiency, and sustainability. Whether for high-speed labeling, error prevention, or seamless integration, the 2200 series is the ultimate solution for enhancing production line performance and operational efficiency.